Product Introduction:

1. The shell adopts 40Cr, through aging treatment, precision machining, with high rigidity, high precision, long life and so on. Allow the minimum pass Phi D115

2. The main drive shaft is made of special alloy material, processed by strict heat treatment process, and finally precision grinding and forming to achieve high stability of transmission.

3. Gear bearings are imported, ensuring the transmission of high torque, low noise.

4. Input and output forms are diverse and flexible, not limited to BT or ER interface, can meet all kinds of precision machining equipment, can be used for milling, drilling, tapping, grinding and other processes of processing.

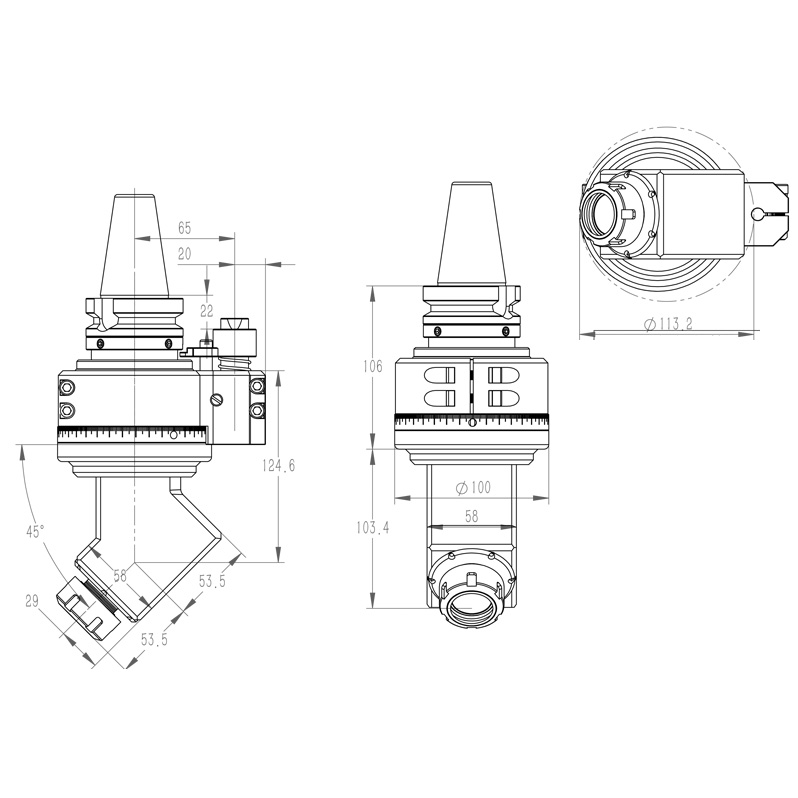

Milling head parameter

Specification Model: DK45-BT40-ER25

Driver shank: BT40/NT40/HSK63A

Other handles: Supported

Peak speed: 6800RPM

Spindle steering: CW-CW

Transmission ratio: 1:1

Through diameter: D115

Clamping range: D1-D16

Tapping range: M6-M14

Peak torque: 46.Nm

Milling head weight: 5.3kg

Inventory: standing stock

Customization: Supported

Previous :DK90-BT40-ER25-210

Next:DK90-BT40-ER25-Z80