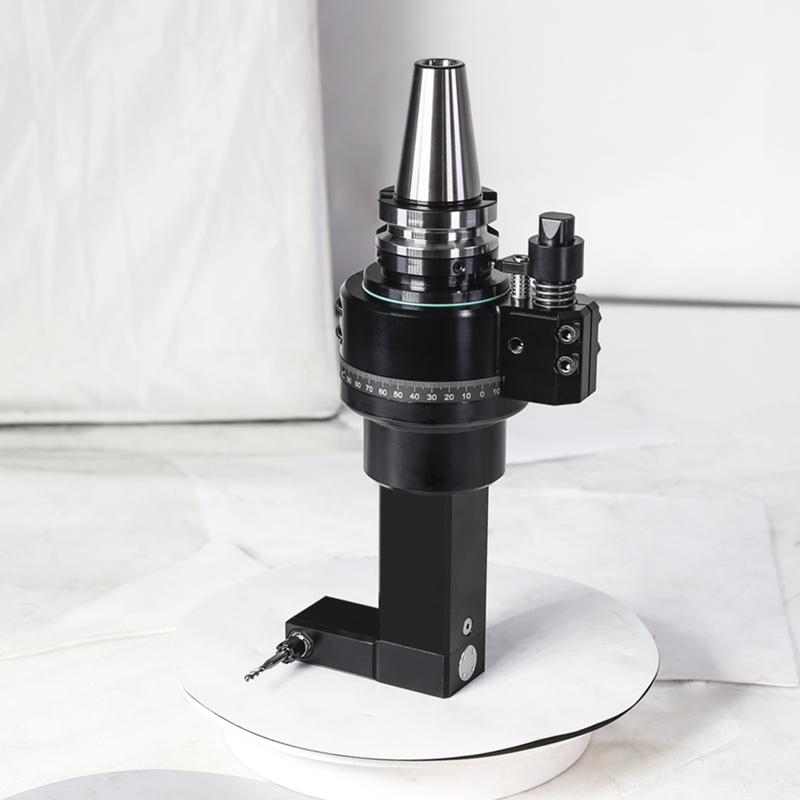

The working principle of the Z-type Angle head is a special Angle head tailored by a special machine tool processing method, which can be processed for special-shaped parts that are difficult to process, and a series of precision transmission mechanisms such as internal gears are used to convert the rotation axis direction of the output shaft to achieve the Angle required for metal processing. There are many kinds of Angle head, and the special Angle head for boring should be selected according to the machining accuracy level. The commonly used processing Angle requirement is 90°, which can reduce the gear wear fatigue caused by the Angle head for a long time processing, and improve the stability during the working period. The boring head/milling cutter is connected with the Angle head by connecting the plane and positioning the short pin. The boring head is a fine-tuning boring tool with a certain amount of adjustment, which can be accurately adjusted to Φ0.02mm, and the whole tool can be very flexible and flexibly adapt to product changes or different product objects. The power is transmitted by the machine spindle through the transmission mechanism to the Angle head and then transferred to the boring tool, Boring/drilling/milling tool According to the program set parameters for cutting, tapping, drilling, milling and other operations.

Processing features: high precision, strong stability, long service life. Can process complex structural parts, grooving, tapping, drilling, milling surface and so on. Such as subframe, precision mold groove, engine block internal processing and so on

Previous p Post:Bay Angle head product maintenance and routine maintenance

Next Chapter:No more!